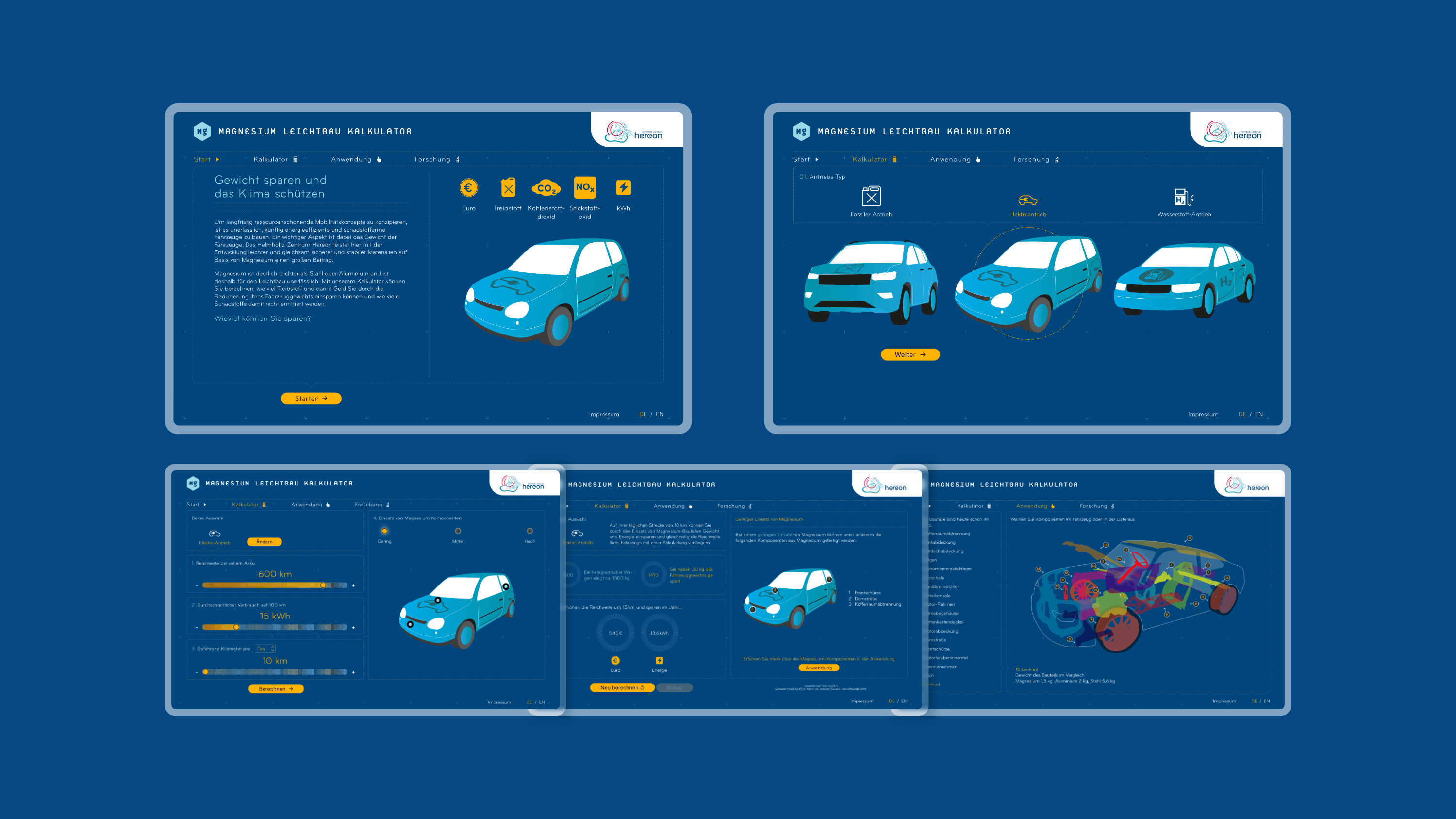

The research work carried out under the umbrella of the Magnesium Innovation Centre (MagiC) at the Helmholtz-Zentrum Hereon is making an important contribution to the development of long-term, resource-saving mobility concepts by developing lightweight, safe and stable magnesium-based materials. In order to communicate the research work of the Helmholtz researchers to a wide audience and to demonstrate the benefits and everyday relevance of the development, we have designed an interactive calculator on behalf of the Helmholtz-Zentrum Hereon, which makes the individual savings and emission reductions through the use of lightweight components in automotive construction comprehensible.